Goodwill Foundry

Gravity Die Casting

Gravity die casting is a manufacturing technique that involves pouring molten metal into a reusable mold. The mold cavity fills with no force other than gravity, and filling can be controlled by tilting the die.

The process of gravity die casting involves:

- Heating the die and spraying coating inside the cavity.

- Melting the metal and conveying it through a ladle.

- Slowly pouring the liquid metal into the cavity.

- Waiting for it to solidify.

- Taking out the part after opening the die.

Goodwill Foundry

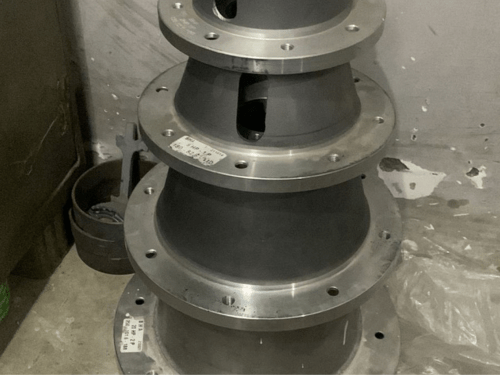

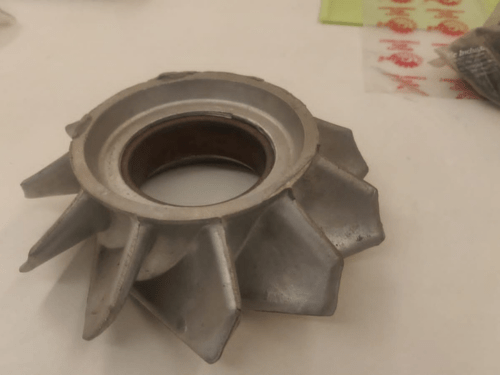

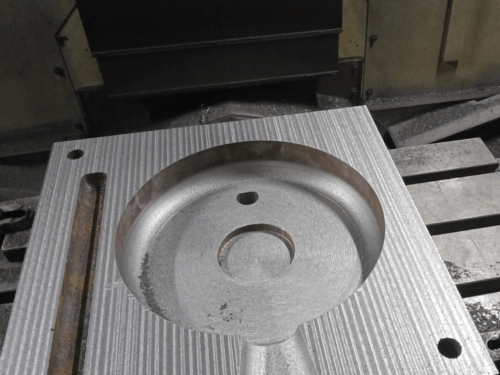

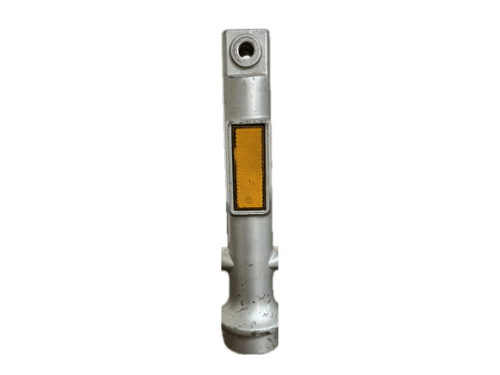

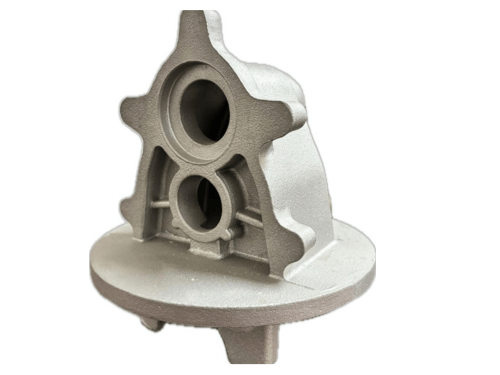

Our Work